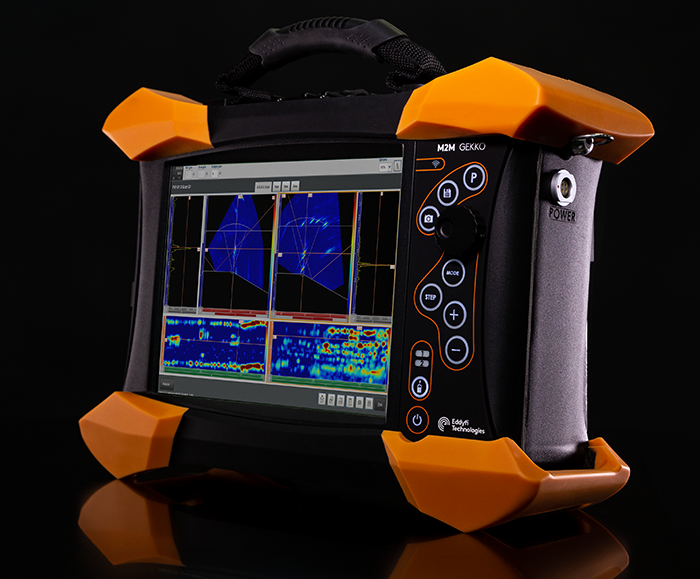

Gekko® is a field-proven flaw detector offering PAUT, UT, TOFD and TFM through the streamlined user interface Capture™. Released in 32:128, 64:64 or 64:128 channel configurations, Gekko combines high-resolution and speed while reducing inspectors’ training time.

Details

Reinventing High-definition Portable UT

Pioneering real-time TFM since 2013, Gekko innovation keeps being driven by market applications. Used in accredited training centers and ready for TFM standards, it benefits from advanced algorithms through a streamlined software user interface (Capture). Simply powerful, Gekko brings the latest technology at your fingertips.

Built for All-level UT Inspectors

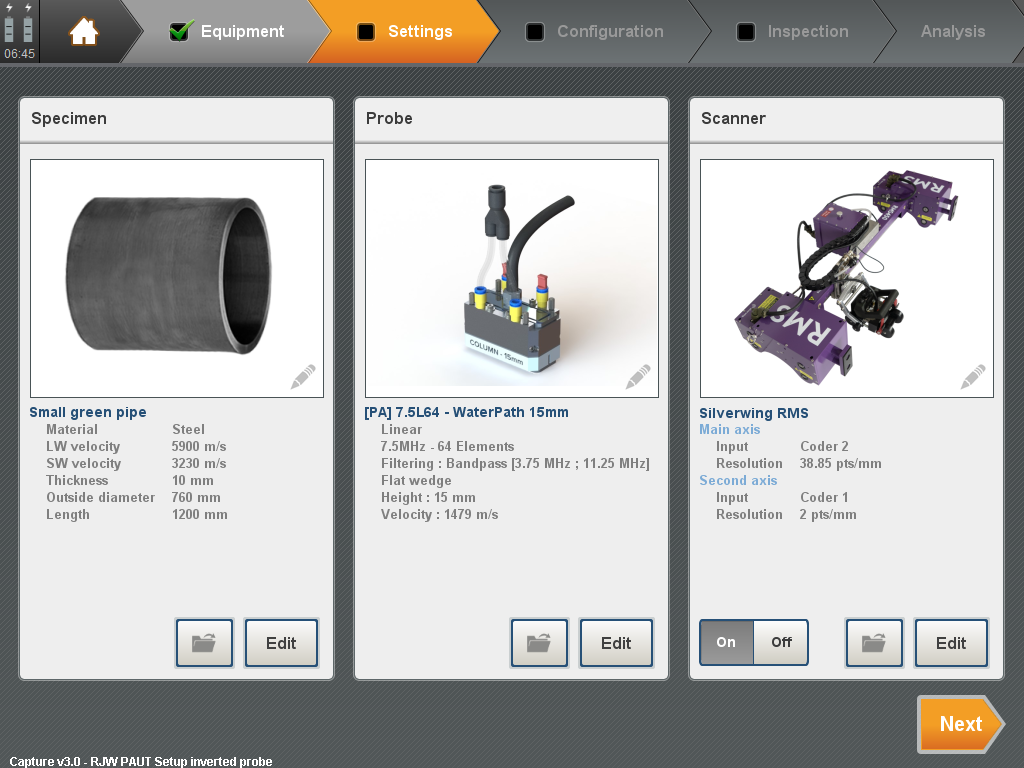

With continuously added tools in one standalone application, Capture eases the inspection process and reduces operator errors. Without the need to use third-party software to load basic and advanced procedures, all-level UT inspectors have access to performance through a visual and guided interface. Capture offers a quick way to improve PAUT knowledge and requires minimum training for phased array inspectors.

Benefits

- Increased accuracy with high-resolution imaging

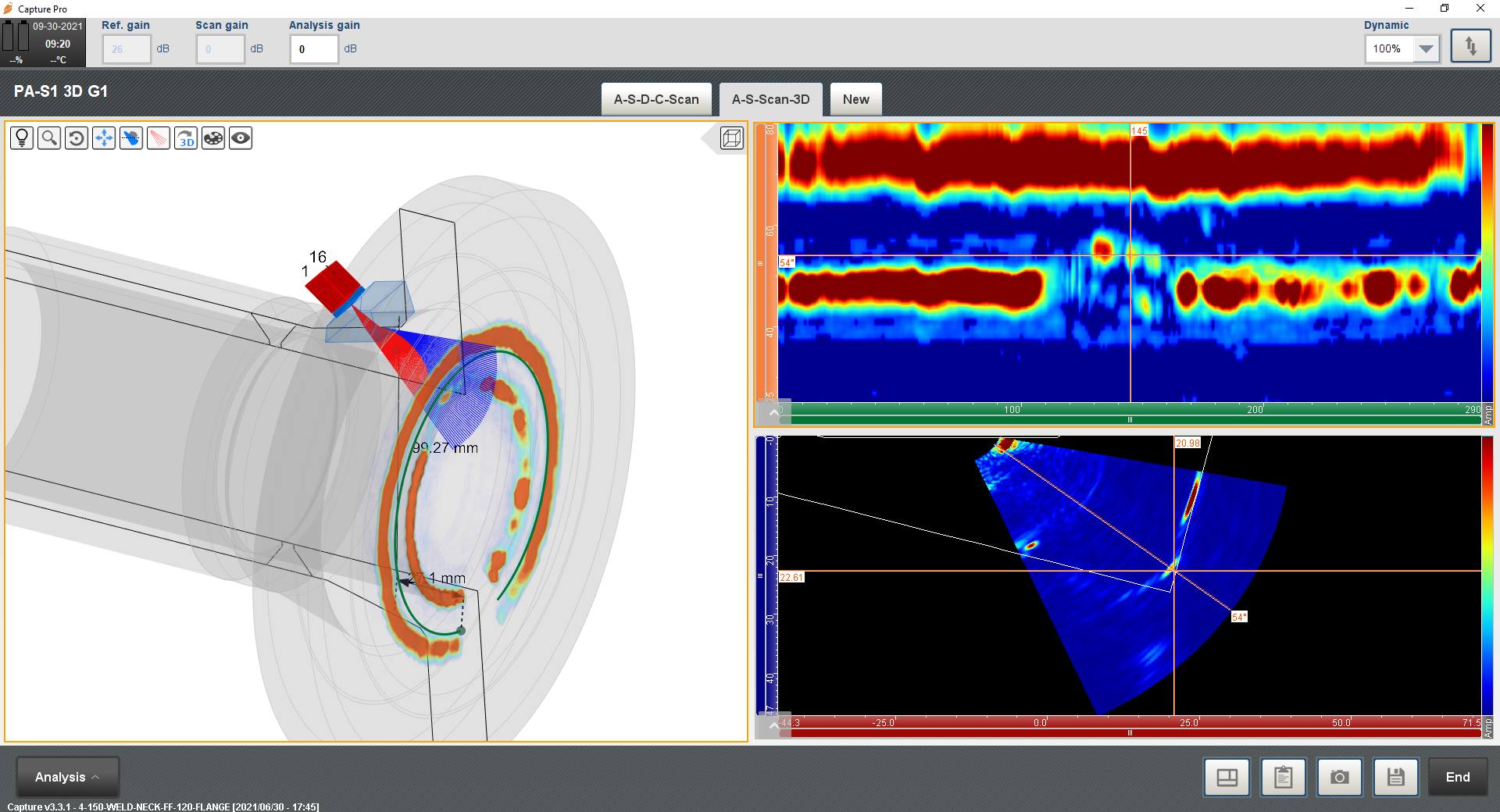

- Advanced defect analysis with Total Focusing Method (TFM)

- Robust field unit with high battery autonomy

- Easy setup with embedded scan plans

- Evolutive software following inspectors feedback

Applications

- Multi-group weld inspection procedures fully covered

- HTHA and hydrogen damages inspection with TFM

- Thick welds and CRA/stainless steel weld inspection enhanced with 128-element aperture

- Corrosion mapping of large areas (up to 5 × 5 m [16.4 × 16.4 ft] / 1 mm [0.04 in] step)

- Complex geometry dedicated solution for nozzle and fillet welds (Y and T joints)

Want to see Gekko in action? Book a demo!

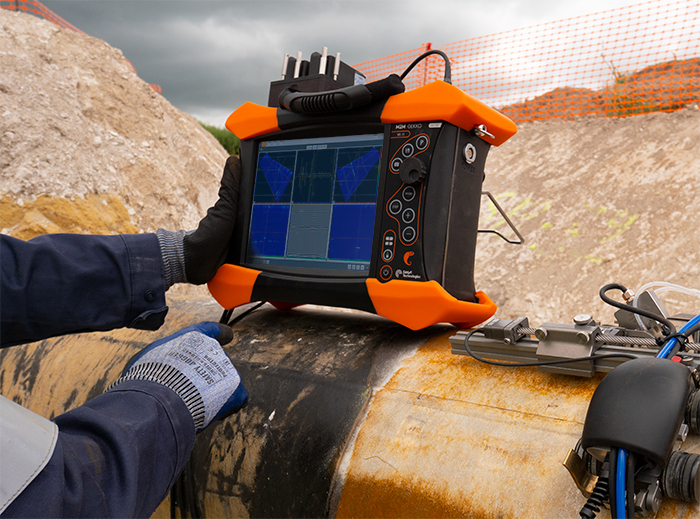

Designed for the Field

Gekko, the #1 PAUT unit with Total Focusing Method (TFM), has been upgraded based on inspectors' feedback. Offering both conventional UT, TOFD and advanced PAUT, Gekko is the most versatile unit adapted to field conditions.

A Complete PAUT Portable Unit

Gekko includes all basics and advanced UT features in a reinforced compact casing designed for field use. It natively comes with conventional UT, TOFD and all beam-forming phased array UT techniques for single-beam and multi-group inspection and its 3-encoded axis capabilities make the Gekko ready for any challenging inspection. This rugged PAUT equipment also offers real-time TFM/FMC (Full Matrix Capture) and Adaptive TFM techniques.

Portable & Robust

Bumpers and connectors are designed for robustness and accessories versatility. The bright resistive touch screen allows outdoor use in rough conditions. Powered by 2 hot-swappable batteries, Gekko now reaches up to 6 hours of autonomy and becomes the ultimate reference in its product range. Designed for IP66 with a drop test rating in accordance with MIL-STD-810G, the rugged enclosure can withstand the harshest site conditions.

Fast Connectivity Solution

The connectivity solutions—dongle-activated Wi-Fi™, USB 3.0 connector and Gigabit Ethernet output—allow to speed up data transfer and to remotely control your inspection in challenging conditions (TeamViewer license included). Moreover, the 256 GB SSD makes the operator’s work very comfortable with unlimited data file size, thus saving time in the field.

Water and Drop Test

No Compromise on Performance

The innovative electronics offers up to 128 channels, great signal quality and TFM resolution for improved detection and confidence. It now reaches a high scan speed and productivity.

Compatible With Most Accessories

Coming with an IPEX type PA connector and a LEMO16 encoder, Gekko is compatible with Eddyfi® accessories and most probes and scanners on the market. For other configurations, Eddyfi can provide the adapter to ensure compatibility with your current accessory.

Ask an ExpertStreamlined Workflow

Powered by Capture, the new generation Gekko has been designed to ease the setup process and save time for the inspectors operating in tough environments.

The newly added onboard scan plan and analysis features join the popular 3-click wizards for evaluation of material velocities, amplitude balancing of the transducer, flat and curved wedge calibration, as well as the automated TCG.

Enriched to offer an all-in-one inspection solution—from application design to inspection and reporting—Capture offers the latest phased array technologies in a couple of clicks.

Unique Features

- Complete toolbox for TFM including TCG calibration

- High-resolution TFM imaging up to 128 elements

- 3-axis nozzle inspection with live overlay display

- 3-axis paintbrush for composite and corrosion mapping

- Live display of fillet weld inspection

- Real-time Adaptive TFM (ATFM) for inspection of wavy surfaces

Exclusive Content

Workshop Capture 3.2 for welds

Pause-café avec Eddyfi | Inspection de soudures à l’aide d’une configuration multigroupes TFM

Coffee Break presented in French

Performance des outils d’analyse Capture pour l'inspection de soudures (PAUT, TOFD et TFM)

Workshop presented in French.

Ultrasons multi-éléments et TFM : puissance combinée pour l'inspection de structures critiques

Workshop presented in French.

Life is better with TFM: How can the game-changing method enhance your inspections in real-time

In this Webinar, you’ll learn:

- How Eddyfi Technologies, as TFM pioneers, implemented new options for real-time TFM in its instruments (such as plane wave imaging -PWI-, etc,),

- How this cutting-edge NDT technique can enhance your NDT inspections

- How codes and standards are accounted for directly in the system to guarantee the compliance of all setup parameters

- How intuitive and easy it is to use TFM within the Capture software, especially with 3D and toolbox analysis.

The webinar includes a presentation of the technique, illustrates the power of the Capture interface, features a demo portion and addresses some of the most frequently-asked questions.

How to simplify welds NDT inspection using Total Focusing Method (TFM) and Phased Array UT (PAUT)

Girth-weld inspections require numerous parameters to be specified on most flaw detectors. The Gekko and Mantis user interface (Capture) solves these challenges. Using off-the-shelf probes, the NDT inspector can quickly configure his unit, scan, and analyze the collected data with confidence.

In this Webinar, you’ll learn:

How fast Capture makes it easy to get ready to scan using ultrasonic techniques such as Total Focusing Methods (TFM) and Phased Array Ultrasonic Testing(PAUT), how streamlined is the analysis of TFM data and how chosen approaches compare.

How adding TFM to a PAUT unit overcome limitations of each technique

A case study: girth-weld inspection setup, data acquisition, and analysis overview

Weld Inspection Paparazzi | World Pipelines Article

This exclusive content discusses the use of ultrasound imaging techniques for pipe welding inspection of varying weld conditions.

Specifications

INSTRUMENT

- 410 × 284 × 126 mm (16.1 × 11.2 × 5.0 in)

- 6.4 kg (14.1 lb)

- 15 V, 5.67 A

- Types: 2 × Li-ion, 94 Wh capacity

- Typical life: up to 6 hours

- 26.4 cm (10.4 in) resistive touchscreen

- 1024 × 768 px screen resolution

- 256 GB SSD

ENVIRONMENT

- Designed for IP66

- 10–45°C (14–113°F)

- w/ batteries: 20–60°C (-4–140°F)

- w/o batteries: 20–70°C (-4–158°F)

- According to MIL-STD-810G