Total Focusing Method (TFM)

How does TFM Work?

The Total Focusing Method (TFM) is an ultrasonic array technique which is used to synthetically focus at every point of a region of interest.

Details

1st Step: Data Collection with Full Matrix Capture (FMC)

- Full Matrix Capture (FMC) is another way of collecting phased array data

- This technique doesn’t require any knowledge of the piece to be inspected (nor shape, nor velocities)

- Each element is just activated (shot) one by one

- All the elements in reception are recorded and thus a Matrix of signal is stored in order to be processed

2nd Step: Reconstruction: Total Focusing Method (TFM)

Main Advantages of TFM

- Optimal focusing and spatial resolution everywhere

- Direct imaging of a large area for one probe position

- All reachable angles with the array simultaneously

- Defect characterisation

- Comprehensive imaging of defect

- 3D imaging

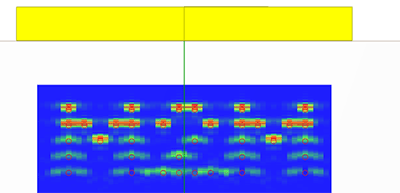

Comparison with Electronic Scanning

Electronic scanning

- 8-element aperture

- Focused along the defects in the middle

- 57 shots

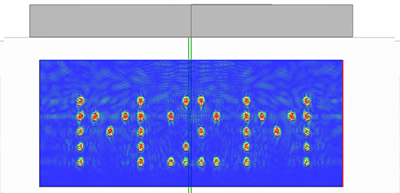

TFM

- 64-element aperture

- Focused everywhere

- 64 shots

Electronic scanning

TFM

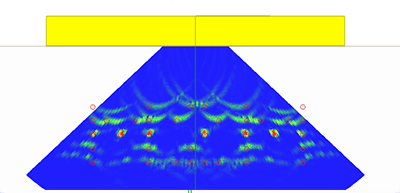

Comparison with Sector Scanning

Sectorial scanning

- 64-element aperture

- Focused along the defects in the middle

- Sectorial between -55° and 55° with 110 shots

TFM

- 64-element aperture

- Focused everywhere

- 64 shots